Regatta Solution recently received an order for a 500 TR Thermax Multi-Energy driven chiller from a premier grow house facility in California. The equipment is…

Energy News

Keep yourself up-to-date

Category: Cogeneration

Another successful Regatta Oil and Gas Installation – Offshore Application – Flare Elimination / Cogeneration!! For more information contact sales@regattasp.com

Regatta at the 2017 Food Processing Expo

Food Processing Expo 2017 was a huge success with more than 2,500 participants in the two-day event held February 8-9 at the Sacramento Convention Center. Andrea…

5 Steps to a Successful Combined Heat and Power (CHP) Project

A message from our CEO, Over the course of Regatta Solutions’ history we have commissioned more Combined Heat and Power (CHP) projects than any other…

Read more about 5 Steps to a Successful Combined Heat and Power (CHP) Project

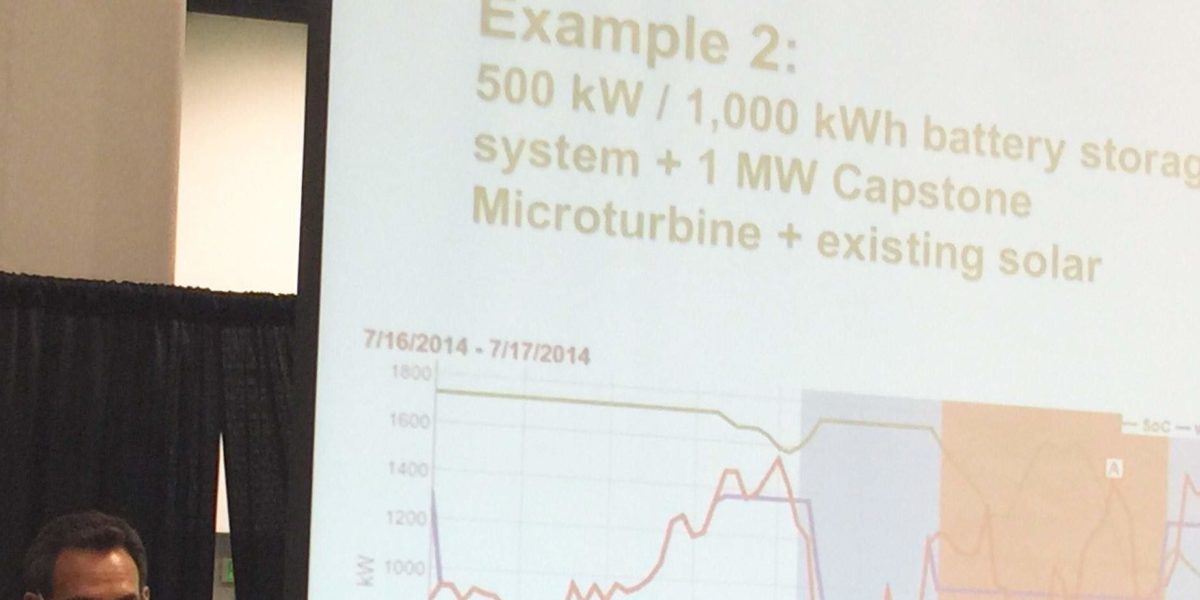

Microgrids Ensure Business Resiliency

Microgrids are the optimal energy solution for sustainability, resilience and cost effectiveness. Steve Acevedo spoke today on real life examples from breweries to manufacturing, to…

May 17, 2016 02:47 PM Eastern Daylight Time LOS ANGELES–(BUSINESS WIRE)–Two California breweries have recently commissioned Regatta Solutions to install Capstone microturbines as a way to achieve…

Capstone to Provide 1MW Microturbine for CCHP at Top-Ranked Pennsylvania College

CHATSWORTH, Calif., Sept. 11, 2015 (GLOBE NEWSWIRE) — Capstone Turbine Corporation (www.capstoneturbine.com) (Nasdaq:CPST), the world’s leading clean technology manufacturer of microturbine energy systems, announced today…

Read more about Capstone to Provide 1MW Microturbine for CCHP at Top-Ranked Pennsylvania College